A small spherical insulator of mass, characterized by its unique physical and electrical properties, plays a crucial role in various applications. Understanding the mass properties, electrical behavior, mechanical strength, thermal characteristics, and diverse uses of these insulators is essential for engineers and researchers working in electrical, mechanical, and thermal systems.

The remarkable properties of small spherical insulators stem from their compact shape, high surface area-to-volume ratio, and the materials used in their construction. These insulators exhibit excellent electrical insulation, mechanical durability, and thermal stability, making them indispensable components in a wide range of industries.

Mass Properties

Small spherical insulators possess mass, a fundamental property representing the quantity of matter they contain. Mass is directly related to the density of the material used to fabricate the insulator. Density is defined as the mass per unit volume and is typically expressed in kilograms per cubic meter (kg/m³).

Common materials employed for small spherical insulators include ceramics, plastics, and glass. Ceramic insulators, such as alumina (Al₂O₃) and zirconia (ZrO₂), exhibit high densities ranging from 3.5 to 4.5 g/cm³. Plastic insulators, such as polyethylene (PE) and polypropylene (PP), have lower densities ranging from 0.9 to 1.2 g/cm³.

Glass insulators, such as borosilicate glass, possess intermediate densities around 2.5 g/cm³.

Electrical Properties

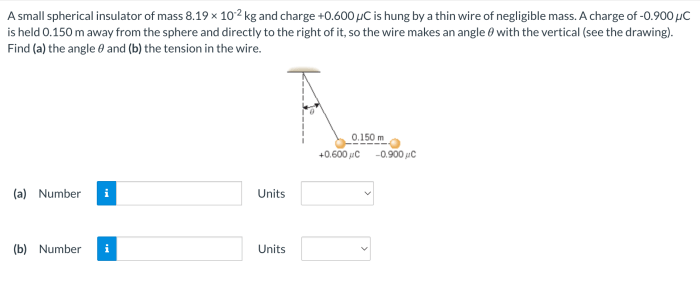

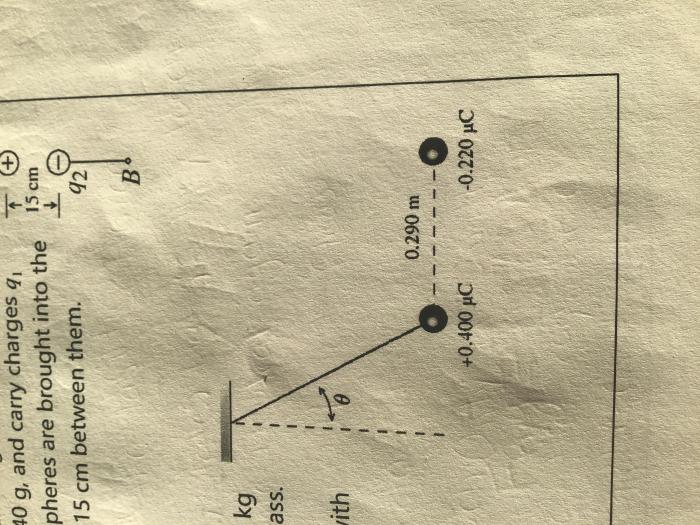

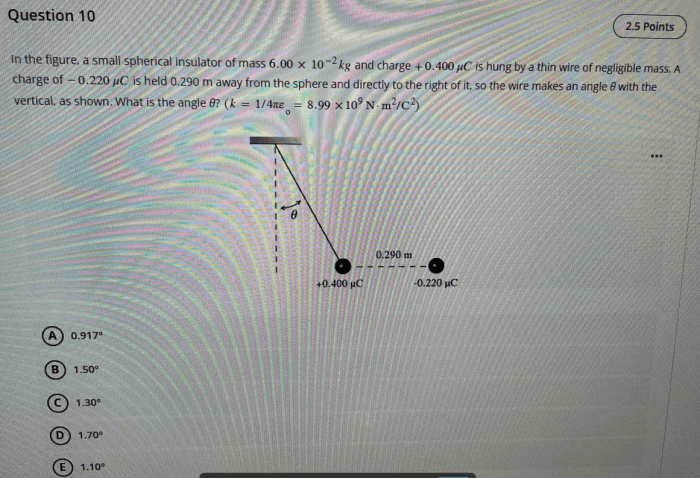

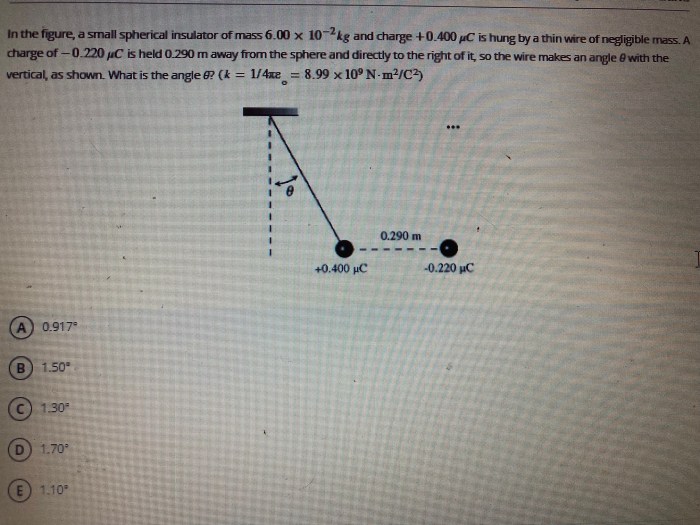

Small spherical insulators are characterized by their excellent insulating properties, which prevent the flow of electric current. This insulating behavior arises from the non-conductive nature of the materials used in their construction. The surface charge distribution on the insulator plays a crucial role in determining its electrical behavior.

When a voltage is applied across an insulator, charges accumulate on its surface. The distribution of these charges depends on the shape and material of the insulator. For small spherical insulators, the surface charge distribution is relatively uniform, resulting in a high electrical resistance.

The electrical breakdown strength of an insulator is a measure of its ability to withstand high voltages without allowing current to flow. Factors influencing the electrical breakdown strength include the material’s dielectric constant, dielectric strength, and thickness.

Mechanical Properties: A Small Spherical Insulator Of Mass

Small spherical insulators possess good mechanical strength and durability, making them suitable for various applications. The mechanical properties of these insulators are influenced by the material’s hardness, toughness, and tensile strength.

Ceramic insulators, such as alumina, are known for their high hardness and resistance to wear. Plastic insulators, such as polyethylene, offer good toughness and flexibility. Glass insulators, such as borosilicate glass, exhibit a combination of strength and thermal stability.

Small spherical insulators are often used in applications where resistance to impact, vibration, and temperature fluctuations is required. For example, they are commonly employed in electrical connectors, sensors, and high-voltage equipment.

Thermal Properties

Small spherical insulators possess thermal properties that contribute to their performance in thermal insulation applications. The thermal conductivity of an insulator measures its ability to conduct heat. Low thermal conductivity is desirable for insulators, as it minimizes heat transfer.

The heat capacity of an insulator represents its ability to store heat. High heat capacity materials can absorb and release significant amounts of heat without experiencing large temperature changes.

Factors influencing the thermal properties of small spherical insulators include the material’s composition, density, and porosity. Ceramic insulators, such as alumina, have low thermal conductivity and high heat capacity, making them effective thermal insulators.

Applications

Small spherical insulators find applications in various industries due to their unique properties. Their electrical insulating properties make them suitable for use in electrical connectors, circuit boards, and high-voltage equipment.

The mechanical strength and durability of small spherical insulators make them ideal for applications where resistance to impact and vibration is required. They are commonly used in sensors, actuators, and automotive components.

The thermal properties of small spherical insulators make them suitable for use in thermal insulation applications. They are employed in heat sinks, thermal barriers, and cryogenic systems.

Detailed FAQs

What are the common materials used for small spherical insulators?

Common materials include ceramics, plastics, and glass, each offering specific advantages in terms of electrical insulation, mechanical strength, and thermal stability.

How does the surface charge distribution affect the electrical behavior of small spherical insulators?

The surface charge distribution influences the electric field around the insulator, affecting its capacitance and breakdown strength. A uniform surface charge distribution results in a more stable electric field and higher breakdown strength.

What factors influence the thermal stability of small spherical insulators?

Factors such as the material’s thermal conductivity, specific heat capacity, and coefficient of thermal expansion affect the insulator’s ability to withstand temperature fluctuations and maintain its structural integrity.